Add to Cart

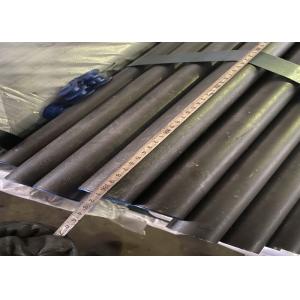

Equivalent Cold Or Hot Drawn 50.80 Mm X 2.3mm Sa 179 Heat Exchanger Steel Tube

Product Description: Generally, domestic boiler companies purchase high-pressure boiler tubes according to GB5310 or enterprise procurement regulations (ordering technical conditions). Non-destructive testing generally adopts eddy current and ultrasonic automatic flaw detection. It is required to conduct eddy current flaw detection for steel pipes one by one. ;Steel pipes shall be subjected to ultrasonic flaw detection one by one, and the flaw detection method shall be in accordance with GB5777 grade, and the acceptance criteria for all specifications of steel pipes shall comply with the regulations of L2 grade; the non-destructive testing of outlet pipes or steel pipes delivered in accordance with ASME SA-213 shall be controlled in accordance with SA-450.

| Seamless Carbon Steel Bolier Tubes for High-Pressure | |

| Application: | For seamless carbon steel bolier and superheater tubes for high-pressure service |

| Size(mm): | O.D.:6.0~114.0 W.T.:1~15 L:max 18000 |

| Chemical Composition | C | Mn | P≤ | S≤ | Si≤ |

| 0.06-0.18 | 0.27-0.63 | 0.035 | 0.035 | 0.25 |

| OD In (mm) | + | - | WT In(mm) | + | - |

| <1(25.4) | 0.10 | 0.10 | ≤1.1/2(38.1) | 20% | 0 |

| 1~1.1/2(25.4~38.1) | 0.15 | 0.15 | >1.1/2(38.1) | 22% | 0 |

| >1.1/2~<2(38.1~50.8) | 0.20 | 0.20 | |||

| 2~<2.1/2(50.8~63.5) | 0.25 | 0.25 | |||

| 2.1/2~<3(63.5~76.2) | 0.30 | 0.30 | |||

| 3~4(76.2~101.6) | 0.38 | 0.38 | |||

| >4~7.1/2(101.6~190.5) | 0.38 | 0.64 | |||

| >7.1/2~9(190.5~228.6) | 0.38 | 1.14 |